Moisture Analysers: Everything You Need to Know

Table of Contents:

What is Moisture Analysis and Why Does It Matter?

Principles of Moisture Analysis

Other Moisture Analysis Methods

Types of Moisture Analysers

Key Features to Consider When Choosing a Moisture Analyser

Applications Across Industries

How to Use a Moisture Analyser: Summary

Calibration: Summary

Choosing the Right Moisture Analyser: Summary

Why Buy from Scales and Balances?

Conclusion

Moisture analysis is one of the most vital steps in ensuring product quality, consistency, and regulatory compliance across industries. Whether you are manufacturing pharmaceuticals, processing food, or testing raw materials, the accurate determination of moisture content can significantly affect your outcomes. In this guide, we explore the principles of moisture analysis, compare analyser types, and explain how to choose the best system for your specific application.

What is Moisture Analysis and Why Does It Matter?:

Accurate moisture analysis, the measurement of water or volatile substances in a material, is critical for product quality, regulatory compliance, and preventing issues like spoilage. Moisture content refers to the amount of water or volatile substances present in a material. Even minor moisture deviations can lead to failed batch tests, spoilage, poor shelf life, or substandard product performance. Accurate moisture analysis is essential for:

-

- Regulatory compliance

- Optimising drying processes

- Ensuring consistency between batches

- Reducing material waste

- Improving product longevity

Moisture analysers are far faster and more precise than traditional drying ovens. For example, when a food production facility in the Midlands reached out to us to help speed up their moisture testing process, we introduced them to the Ohaus MB92 Moisture Analyser. Their line technician had been spending over 3 hours per batch using a standard oven method. With the MB92, they reduced testing time to just 12 minutes, allowing for in-process moisture checks rather than waiting until the end. Another example comes from Fold Hill Foods Ltd., a well-known pet food manufacturer. They transitioned from a traditional drying oven method to a digital moisture analyser setup following on-site guidance from Stuart Kemp. This change helped them tighten moisture control across batches, reduce energy usage, and cut laboratory expenditure, all without slowing down throughput. Traditional drying ovens often fail to deliver the accuracy or speed required in modern production. That is why moisture analysers are becoming the preferred solution across a wide range of industries.

Principles of Moisture Analysis:

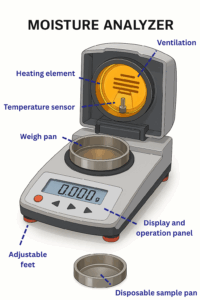

The most common principle behind moisture analysis in modern analysers is Loss on Drying (LOD), which involves heating a sample to determine its moisture content by weight difference. Loss on Drying (LOD) The most common method used in modern moisture analysers is Loss on Drying. This involves heating a sample to evaporate moisture and then calculating the percentage loss in weight. A typical moisture analyser includes:

- A high-precision balance to measure sample weight

- A heating source, often halogen or infrared

- A control system that monitors and ends the test at the appropriate point

The process usually follows these steps:

- Tare the empty sample pan

- Load the sample evenly

- Begin heating using a set temperature profile

- The analyser continuously weighs the sample

- Once weight loss stabilises, the test ends

- Final moisture content is calculated automatically

Factors Influencing LOD Results

- Sample Preparation: Uniform particle size and spreading affect consistency.

🔧 Tip from the field: One of our clients in the plastics industry had been getting erratic readings across batches because their samples weren’t being ground finely enough before testing. Once they adjusted their prep method, results stabilised instantly. Moisture analysers are accurate, but only if the sample is uniform. - Heating Profile: Too high a temperature may degrade the sample

- Endpoint Criteria: The analyser must detect when weight loss stabilises

Other Moisture Analysis Methods

While LOD is the most common method for routine use, other techniques include:

- Karl Fischer Titration vs. Moisture Analysers: What’s Best for Your Application?: Ideal for low-moisture or specific chemical analysis

- Infrared Spectroscopy: Suitable for fast, non-destructive testing

- Microwave Drying: Often used in lab-based research or specialised production

We explore these in more detail in dedicated articles for readers needing advanced or niche methods.

Types of Moisture Analysers:

Moisture analysers vary primarily by their heating method, each offering distinct advantages for different applications and sample types. Moisture analysers differ by the heating method they use, and each type offers distinct advantages:

Want to understand more about their uses? See our guide on Understanding Moisture Balances: Applications and Benefits.

Key Features to Consider When Choosing a Moisture Analyser

- Accuracy and Readability: Higher readability (e.g., 0.001%) allows for tighter tolerances in critical applications.

- Capacity: Analysers typically range from 30 g to 200 g. Choose according to the average sample size.

- Heating Control: Adjustable ramp rates and temperature profiles help fine-tune the analysis.

- Endpoint Detection: Criteria such as stable weight or fixed time can be set depending on the application.

- Data and Connectivity: Many modern models offer:USB or Ethernet output GLP/GMP compliant reports Integration with LIMS or ERP systems

- Calibration: Regular calibration ensures continued accuracy. Some models feature built-in calibration weights and temperature sensors.

- Compliance and Documentation: Pharmaceutical and food sectors often require EN or ISO standards compliance, and automatic documentation is vital.

Applications Across Industries

Moisture analysers serve a wide range of sectors. Here are just a few examples:

- Food and Beverage: Checking moisture in coffee, flour, meats; controlling shelf life and spoilage risk.

- Pharmaceuticals: Ensuring stability of raw powders; verifying compliance with pharmacopeial standards.

- Chemicals: Measuring water content in adhesives or solvents; characterising raw materials.

- Plastics: Verifying pre-moulding dryness; ensuring strength and consistency.

- Agriculture: Grain and feed moisture analysis; soil and fertiliser content testing.

Interested in how moisture analysers are specifically used in food manufacturing? Read our blog: Moisture Analysers for Food Manufacturing.

How to Use a Moisture Analyser: Summary

One client in the food packaging sector found that switching from an oven to a programmable moisture analyser reduced their testing time by over 70%. It also cut down on operator errors, improving accuracy and throughput. To understand the full process, see our comparison of Moisture Analysers vs. Traditional Drying Methods.

Calibration: Summary

Calibration is a crucial, often overlooked, part of ensuring reliable data. One pharmaceutical client identified a months-long error in heating uniformity only after implementing scheduled calibration checks. Read more in our blog on Moisture Analyser Calibration Explained.

Choosing the Right Moisture Analyser: Summary

Consider the material, required precision, compliance needs, and available budget.

Why Buy from Scales and Balances?

At scalesandbalances.co.uk, we specialise in high-performance weighing and moisture analysis systems. Our expert team offers:

- Free consultation on selecting the best analyser

- Full support for calibration and maintenance

- A wide range of models from trusted manufacturers like A&D, Ohaus, and Adam Equipment

Our customers value our in-depth product knowledge, rapid response times, and hands-on support throughout the purchasing and ownership journey. Explore our full range of moisture analysers or get in touch with our team for tailored advice.

Conclusion

Moisture analysers have become an essential tool for laboratories and industrial workflows where precision, speed, and traceability matter. By understanding the methods, applications, and features available, you can select a solution that ensures quality, compliance, and efficiency. If you would like help selecting the right analyser, or you have technical questions about calibration, please reach out. Our team is always ready to help you make the right choice.

Final Thoughts

Moisture analysers are more than just lab tools. They are precision instruments that improve quality, reduce waste, and ensure compliance.

This guide draws on the extensive knowledge of Stuart Kemp, Operations Director at Blake and Boughton Ltd. Stuart’s 17 years of hands-on weighing experience spans a vast range, from ultra-micro balances with a readability of 0.001mg right up to industrial weighbridges exceeding 20 tonnes (over 20,000kg). This comprehensive experience, combined with the over 100 years of collective expertise of our in-house engineers, all backed by our established mother company, D Brash and Sons Ltd., founded in 1879, ensures that the advice and products from scalesandbalances.co.uk are built on a foundation of deep industry knowledge.

We align ourselves with key industry standards, and you can find more information about relevant auditing bodies such as SALSA (Safe and Local Supplier Approval), BRC (British Retail Consortium), and ISO (International Organization for Standardization).

Together with the scalesandbalances.co.uk team, Stuart ensures all our moisture analysers are calibrated, certified, and backed by advice you can trust.

➡️ Contact us for tailored moisture analysis advice, or browse our full moisture analyser range.

Other Moisture analyser blogs:

Moisture Analysers vs. Traditional Drying Methods: A Comparative Study

Karl Fischer Titration vs. Moisture Analysers: What’s Best for Your Application?

)