Description

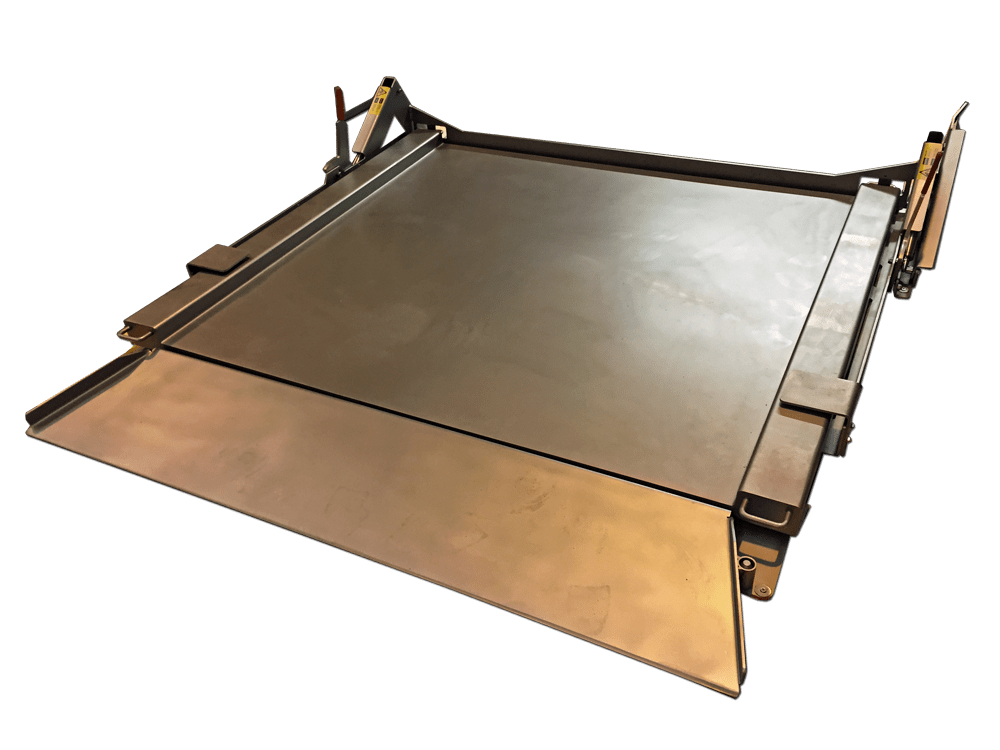

The Ludi Lift-Up Stainless Steel Floor Scales, Drive-In Platform Weighing Scale for Hygienic Washdown applications.

With a high quality, full stainless steel construction and IP69K rated loadcells, the Baykon Ludi Lift Up Stainless Steel Floor Scales, Lift-Up Drive-In (LUDI) Platform Weighing Scale complies to GMP and HACCP production standards making it ideal for harsh, wet and sanitary environments where hygienic cleaning is vital.

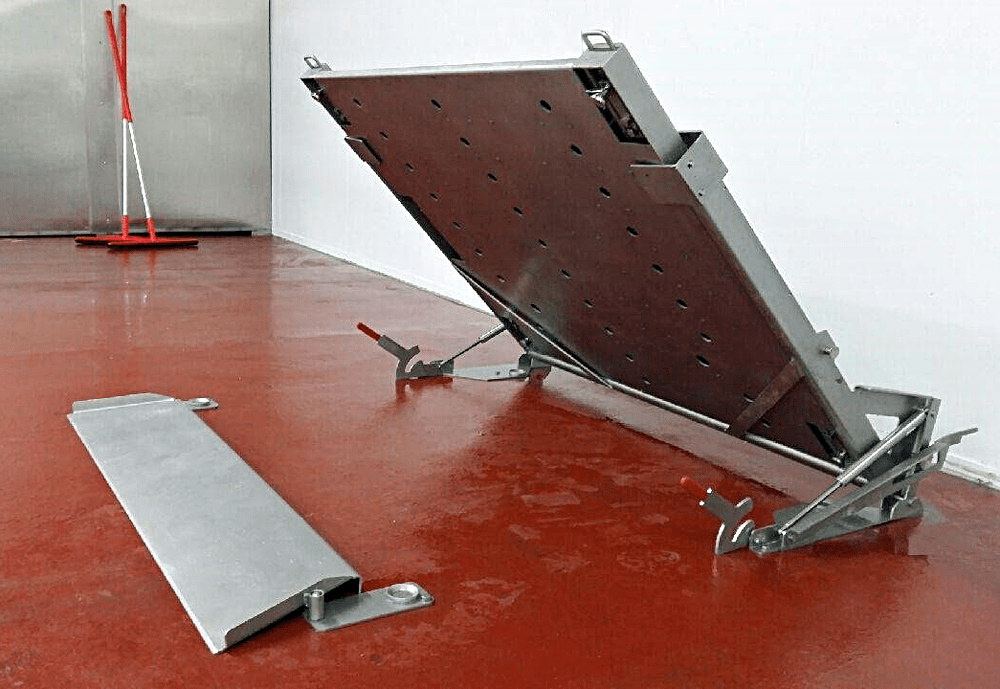

Designed with incorporated lifting abilities that are supported by hydraulic internals means this enables the platform to be raised to a safe and easy 90 degree angle with minimal force and to be locked in place for safety. Once lifted the operator has clear 360 degree access for the deep cleaning required to eliminate hygiene and contamination risks.

The OIML approved LUDI has a premium quality and robust build that makes it ideal for Pharma, food production and cosmetic industries. It is available in dimensions ranging from 850mm to 1500mm and in capacities from 300kg to 1500kg.

Ideal for many production environments where easy cleaning and reduced manual handling are essential.

Suited to Food Production, Pharmaceutical, Chemical and many other industries.

These can also be made into ATEX Zone 1/21 or Zone 2/22, please get in touch if this is a requirement.

Capacity Options: 100kg, 150kg, 300kg, 600kg, 1500kg (UDL Spread Load)

Construction: 304 grade stainless steel with ultra smooth finish. Seamless frame with 5mm top plate, laminated base and gas assist lifting mechanism.

Finish: Professional – dirt trap free – ultra smooth processed finish.

Loadcells: 4 off Flintec OIML approved IP69 rated stainless steel loadcells, 5m of high quality cable with steel armoured braiding

Feet: Stainless Steel mounting feet.

Junction Box: Stainless steel sealed junction box and summing board

Ramp: Supplied with one stainless ramp (300mm long)

- Premium quality manufacturing

- Fully stainless steel washdown construction

- IP69K stainless steel OIML approved loadcells

- Stainless gas assist for effortless lifting

- Easy access for deep cleaning & maintenance

- Ultra smooth processed surface for hygiene

- Supplied with 1 ramp as standard

- Low Profile – only 45mm High

- Ramp Length – 300mm

- 12 month manufacturer’s warranty

- Various standard sizes and capacities

MPN/Dimensions:

LUDI8585 Weighing Area: 850mm x 850mm

Footprint: 1300mm x 1010mm

LUDI1010 Weighing Area: 1000mm x 1000mm

Footprint: 1450mm x 1200mm

LUDI1212 Weighing Area: 1250mm x 1250mm

Footprint: 1700mm x 1450mm

LUDI1512 Weighing Area: 1500mm x 1250mm

Footprint: 1950mm x 1450mm

Height (Floor to Weighing Area): 45mm

Ramp Length: 300mm

Feefo 5.0* 1000+ reviews

Feefo 5.0* 1000+ reviews UK wide delivery on all products

UK wide delivery on all products Products can be fully calibrated & certified

Products can be fully calibrated & certified Service & repairs at competitive prices

Service & repairs at competitive prices Find a better price and we will try and beat it

Find a better price and we will try and beat it

Reviews

There are no reviews yet.