Description

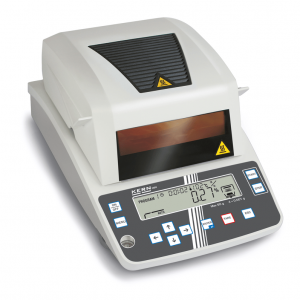

What is the Adam PMB Moisture Analyser?

Adam’s PMB is a high accuracy moisture analyser with simple operation and rapid response time. Available in three capacities, the PMB has an internal memory for storing up to 49 different recipes and 99 test results.

What are the benefits of using the PMB?

With simple operation and rapid response time, PMB moisture analysers offer the top value in their class. The automatic test-setting function enables easy recall for frequent testing of the same items without additional user programming. USB and RS-232 interfaces provide computer and printer connections to store test programs and results. A single 400-watt halogen bulb heats samples in 1 °C selectable increments. Three heating options give users the flexibility to customise test methods and temperatures for different materials.

Feefo 5.0* 1000+ reviews

Feefo 5.0* 1000+ reviews UK wide delivery on all products

UK wide delivery on all products Products can be fully calibrated & certified

Products can be fully calibrated & certified Service & repairs at competitive prices

Service & repairs at competitive prices Find a better price and we will try and beat it

Find a better price and we will try and beat it

Reviews

There are no reviews yet.